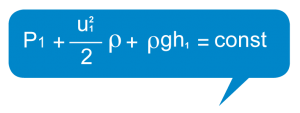

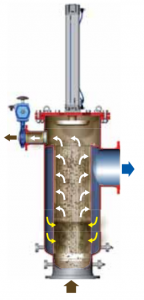

Filter operation is based on the Bernoulli equation which describes behaviour of the non-viscous fluid. The increase of fluid velocity is proportional to the pressure drop.

filtr samoczyszczący

filtr samoczyszczący

The Bernoulli self-cleaning filter is equipped with a disk mounted on a pneumatic cylinder. This allows the contactless, automatic and continuous cleaning of the filter without the need for human intervention.

The disk is moved by the piston that generates a high local increase of flow velocity between the rinsing disk as it moves to the filter inlet. This results in a pressure drop, which allows to clean contactless and releasing of the particles through the rinsing valve. When it is open, it generates a pressure difference, which results in a directed flow of particles towards the outlet.

Thanks to construction based on fluid mechanics the filter produces only a small pressure drop in the system. This results in energy savings compared to the conventional backwash systems. The amount of water for cleaning is so little that the system can be operated without any additional investment in plant modification. The self-cleaning filter is equipped with a multifunctional electronic system that control all functions and gives the opportunity of improvement and optimization. The manual control is also possible.

krone

Advantages of self-cleaning filter:

- Flow rate up to 7500 m3/h in a single installation

- Process pressure from 0.3 to 25 bar

- Continuous process

- Very low value of pressure difference during continuous process (even below 0.1 bar)

- Short, adjustable cleaning steps and minimum pressure drops in the system during rinsing

- Positive energy balance due to low pressure difference during filtration

Filtration and cleaning steps:

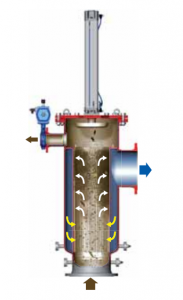

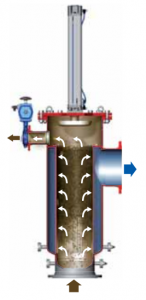

1. Filtration phase

In accordance with fluid mechanics the particles settle on the filter screen from the top to the bottom. Due to the construction of the filter any particles stop in the inlet spigot. This phase is characterized by very low pressure drop.

filtr samoczyszczący

filtr samoczyszczący

filtr samoczyszczący

filtr samoczyszczący

2. Last phase of filtration, start of the rinsing step

The rinsing phase is initiated by a programmed timer or activated by a pressure difference sensor before any filter occlusion reduces the flow rate. In the pre-rinsing step, the rinsing valve opens and generate pressure difference which results in leaching and removal of large particles. Filtration continues without the need for rinsing break. The flow rate depends on the hole in the outlet spigot.

filtr samoczyszczący

filtr samoczyszczący

filtr samoczyszczący

filtr samoczyszczący

3. Basic rinsing phase

The rinsing valve is open. The pneumatically operated piston with the rinsing disk moves to the filter screen (this may take about 5 seconds). High increase of local velocity between the disk and the filter generates a static pressure drop (Bernoulli effect) on the filtrate side. Only to some extent the external pressure on the filtrate side exceeds the pressure between the disk and the filter screen. Along with the increase of the flow rate this leads to the housing clearing. Due to the pressure difference contamination is removed from the filter through an open rinsing valve .

filtr samoczyszczący

filtr samoczysz cząc

cząc

filtr samoczyszczący

filtr samoczyszczący

4. Final rinsing phase

While the rinsing disk moves to its initial position, the rinsing valve is open. This allows the free flow of pollutant particles.

filtr samoczyszczący

filtr samoczyszczący

filtr samoczyszczący

filtr samoczyszczący

Photos from the installation

|

|

|

tak

The Bernoulli self-cleaning filter is widely used in the industry. It is used to remove particles from highly contaminated process water and other liquids such as natural reservoirs (sea, rivers), heating and cooling systems. The filter works at a pressure of 0.3 bar and is characterized by low pressure drops, high flow rates, simple and durable construction, high efficiency, low weight and space-saving design.

filtr samoczyszczący

Areas of application:

Industrial processes:

- Chemical industry

- Fertilizer industry

- Petrochemical industry

- Plastic transformation

- Automotive industry

- Food industry

- Grout production

- Aluminum industry

- Ironworks

- Mineral oil filtration

- Reverse osmosis process protection

- Demineralized water filtration

- Water desalination plants protection

Power plants:

- biomass

- carbon

- gas

- nuclear

Sewage treatment plants:

- Surface water filtration

- Industrial water filtration

Ship industry:

- Circulation cooling

- Water purification

- Ballast water filtration

- In-shore

- FSRU

- REGAS